Laser cut design is an innovation that uses laser technology in order to cut different shapes. It can be used in many fields including jewellery making, woodworking, leather working and other crafts. A laser cutter (or simply cutters) cuts a piece of any type of material through a controlled beam of laser light. Although laser cutters have been around for years, the advent of the Internet has made them more affordable and therefore available for home use.

Methods of Laser Cutting

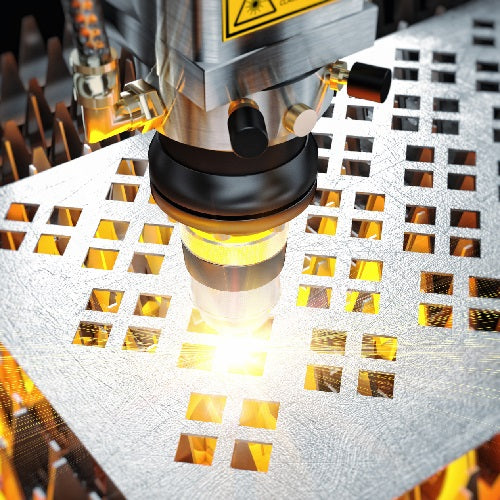

The laser cut design is a contrived example of the method of laser engraving. Laser technology involves using a controlled beam of light to melt the material being cut. Once this happens, the piece of metal is then moved, with the laser, over the piece that was engraved, creating the exact shape and cut.

Types of Laser Cut Designs

There are two main types of laser cut designs.

- One is a line laser cut design. In this case, the laser cut produces a straight line. A lot of this kind of laser cut designs are used in automobile body kits. In addition, they can also be used for other things, such as jewellery or signs, to create ornate patterns.

- The other type of laser cut design is a thermograph-mable laser cut design. This is where the laser cut actually melts the material being cut. Because of this, it is often used to create logos, lettering, iconography, etc.

The process is very similar to that of a cookie cutter, where you place together two pieces of your target material (in this case, metal), outline them with stencils and then cut them out with the laser cut machine. However, this process allows the designer to control the depth of each individual piece, which results in a high level of precision.

Computer aided laser cut designs

Another way to cut using this technique is to do so with a machine that does the job at the same pace as your computer. Computer aided laser cut designs, or CADs, are becoming more popular because of the time savings they provide. Most metal fabrication shops use computers because they save on labor costs as well. By the same token, when you use the CAD program, the operator controlling the laser cut simply needs to make a few keystrokes, much like a typical pen and paper combination, to complete the design.

This type of cutting not only produces accurate, professional looking metal products, but they are also safe to work with. These cuts don't require cutting through the metal, which is typically what leads to contamination and safety issues. In fact, the only thing exposed during a CNC project is the thin sheet of metal underneath the designs. This is usually protected by a UV shield.

Advantages

- This process has many advantages over traditional techniques.

- For one, the products you can create using a CNC machine are far more consistent in their quality.

- Since every single piece is created precisely and carefully, it will be easy to see a unique product every time you look at it.

- You won't have to spend hours or days trying to perfect a single design.

- Each laser cut design is typically broken down into many small parts, which can be used to create many different products.

When you design with laser cut technology, it makes it easy to produce beautiful metal products from a computer. You can create many different products for your customers, or you can sell them as scrap metal. The choice is yours.

If you're interested in metal fabrication or in starting a business selling custom metal fabrication products, there is no reason why you shouldn't consider a CNC machine today. All you need is an interest in the subject and a few tools to get started.